Our History

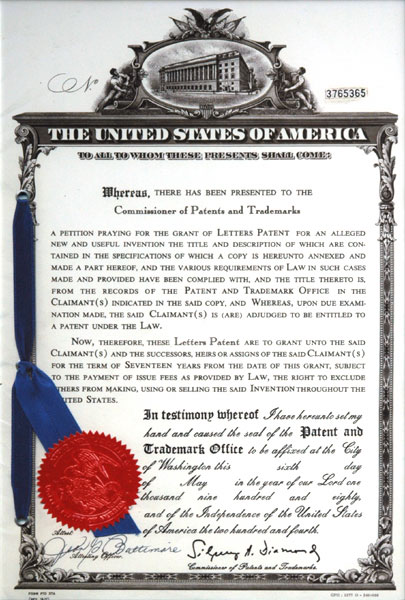

At EPCO, we’ve called Fort Wayne, Indiana home since 1980, when we purchased Gilbaum Manufacturing, the patent holder for the bow eye and lifting assembly designs. SInce then, our product lineup has grown to include stern and mooring eyes, lifting eyes and assemblies, and pontoon test plugs and couplers—all proudly made in the USA.

Now, we’re the world’s largest single manufacturer of stainless steel bow and stern eyes for recreational boats. We specialize in manufacturing more than 800 different bow and stern eyes, as well as custom products—all made to the exacting dimensions designed by our customers.